随着全球汽车和卡车产量达到9,500万辆(2016年),汽车部门在所有的耐候老化测试中占了很大的份额。此外,再加上摩托车、农场和建筑越野车辆、军用、商用航空和休闲交通工具(船舶、雪地摩托等)等相关产业,也都面临着类似的测试需求。

“行动全球化,思考(和采购)本地化”要求我们在全球范围内提供仪器测试和服务以及支持;Atlas遍布全球的服务渠道许多客户愿意选择我们作为汽车耐候技术供应商的关键因素之一。

汽车外饰件应用

汽车涂层

交通工具涂层测试是耐候老化主要的应用领域。各种化学物质的单涂层和底涂+透明涂层(BC/CC)系统在汽车和卡车应用中占主要地位,而凝胶涂层则是休闲用船只的常用产品。这包括一开始的原厂的涂层和售后修复涂层。此外相比于传统经处理过的钢材,外部基材的变化诸如加入复合材料和铝,也增加了对此前已认可的油漆系统的耐候性测试的需求。

- 汽车漆的户外曝晒测试通常在subtropical South Florida 的黑箱中进行。把涂漆面板放在一个底部敞开黑色箱子的顶部表面,模拟汽车车身的密闭空间和温度分布。

- 汽车漆系统和涂料的实验室耐候老化主要是针对OEM或其他(如SAE、VDA、JASO)标准的氙弧灯测试方法,采用Atlas Ci系列Weather-Ometer、Xenotest型号或SUNTEST XXL+ ST测试方法或材料规格中通常会指定特定的型号,并且需要定义配置。某些传统测试是采用现在已过时的阳光碳弧技术进行的,但Atlas仍可提供氙灯和碳弧的商业实验室测试。

- 交通工具涂层系统的腐蚀测试主要针对OEM或其他(如SAE、VDA、JASO)标准的腐蚀测试方法,使用了Atlas盐雾腐蚀试验箱进行。汽车测试通常涉及复杂的湿/干周期、温度周期、电解质喷雾等。AtlasBCX腐蚀试验箱满足许多基本的循环测试,但更复杂的方法需要CCX腐蚀试验箱,为特定的测试方法进行适当的配置,有一系列大小不同的箱体可选。Atlas为特定的测试方法提供了腐蚀测试服务。

包围和车身嵌板车体</6452

- 已涂漆或免喷涂(MIC)系统使用从原件上取下的较小样品进行实验室耐候老化测试,与油漆系统一样。

- 整个车体包围和车身嵌板通常在南佛罗里达和亚利桑那等户外站点进行曝晒,按照它们的装车方向垂直安放。

汽车外部照明

- 车头和车尾灯组件的镜片和反射灯碗按照SAE J576的要求在佛罗里达和亚利桑那户外进行曝晒。

- 外部照明组件在实验室氙灯老化仪中进行曝晒测试,以满足OEM的要求。Ci5000系列Weather-Ometer氙灯老化仪对于大多数照明部件来说足够大,否则就要对OEM产品规格进行户外曝晒测试。

外部装饰件、标识、耐候密封条和垫圈

- 外部装饰组件、标识、反射镜外罩、车顶行李架和耐候密封条的实验室耐候老化主要是针对OEM或其他(如SAE、VDA、JASO)标准的氙灯测试方法,采用Atlas Ci系列Weather-Ometer、Xenotest型号或SUNTEST XXL+ ST;测试方法或材料规格中通常会指定特定的型号,并且需要定义配置。某些日本OEM传统测试仍使用阳光碳弧仪器(开发于20世纪30年代,并在1990年代被Atlas淘汰),然而Atlas仍能提供氙灯和碳弧灯的商业实验室测试。

- 利用Atlas金属卤化物照明系统可对日光热负荷的影响进行测试,这种系统可安装在环境试验仓和风洞中。

汽车玻璃

汽车玻璃

- 挡风玻璃、侧窗、后窗、天窗和全景天窗系统的户外静态曝晒通常在亚利桑那州和南佛罗里达测试站点进行。汽车玻璃对车厢内部的影响通常是在跟踪太阳的旋转平台上进行整车曝晒测试。

- 层压和有色玻璃的小试样加速曝晒测试也通常在亚利桑那州Atlas/DSET Laboratories的EMMA/EMMAQUA等日光聚光仪器上进行。

引擎室、传动链、车轮组件

- 虽然通常主要暴露在间接反射的太阳辐照中,但诸如软管、电线、皮带和聚合物外壳等聚合物引擎室部件,也经常使用xenon arc按照OEM规格耐候老化标准进行测试。

- 金属引擎室、传动链、车轮和刹车组件一般采用OEM腐蚀测试方法进行腐蚀测试。发动机起动器和螺线管等电气部件通常在电力驱动状态下进行腐蚀试验。

- 电动汽车(EV)和混合动力(HEV)组件,如电池、连接器模块和终端、驱动马达等,都是作为部件按照OEM测试方法进行腐蚀测试。除此之外,则使用Atlas步入式/驶入式定制腐蚀试验箱,用于车身或整车腐蚀测试。*

*汽车腐蚀测试通常涉及复杂的湿/干周期、温度循环、电解质喷雾等。AtlasBCX腐蚀试验箱满足许多基本的循环和所有稳态测试。更复杂的测试周期则需要CCX腐蚀试验箱,根据特定的测试方法进行适当配置,有一系列大小不同的箱体可选。Atlas为特定的测试方法提供了腐蚀测试服务。

汽车内饰件应用

汽车内饰件应用

仪表板和门板、气囊盖、硬饰件

- 仪表板(IP)、门板和安全气囊的表面覆层材料经过耐光性(如褪色、变色、光泽、粘性等)和由汽车玻璃过滤的日光辐照所造成的降解测试,结合典型的车厢内温度和湿度条件。主要使用氙灯老化箱进行测试,以达到OEM的规格。

- 如有要求,户外测试通常是在一个控制方位太阳跟踪IP/DP 箱中进行,模拟车厢内的情况。另一种选择是“间接”耐候老化静态曝晒,自然阳光透过玻璃曝晒样品。

地毯、衬垫、顶衬

地毯、衬垫、顶衬

- 纺织品主要采用xenon arc氙灯老化仪根据OEM规格进行测试。

- 纺织品也可按照OEM标准在IP/DP 箱中或通过玻璃将样品曝晒在自然阳光下的“间接”耐候老化静态曝晒进行测试。

内饰电子部件

内饰电子部件包括仪表板显示系统、无线电和娱乐系统、导航、驾驶员信息和驾驶员辅助显示器、蜂窝网络和无线网络等。

- 大多数汽车内部电子产品都采用实验室氙灯老化仪进行测试,以满足OEM的要求。摩托车的电子产品等也需要满足OEM对耐候性测试的要求。

- 正在开发中的新传感器和显示技术,如驾驶员辅助、自动驾驶汽车、平视显示器和OLED仪表面板,可能需要额外的定制耐久性测试。

安全部件

乘客被动安全约束系统如安全带组件,要满足政府、工业和/或OEM对光/紫外线辐照和腐蚀测试以及阻燃性的要求。

- 在美国,FMVSS 209 - 座椅安全带部件——轿车、多用途客车、卡车和公共汽车要求进行紫外线曝晒测试,使用ASTM G23 Type E——日光碳弧灯装置。Atlas为这一要求提供了实验室商业化曝晒测试。其他国家可能要求使用氙灯老化仪或荧光紫外老化仪(UVTest)进行测试。

- FMVSS 209要求按照ASTM B117 - 操作盐雾(雾)装置的标准做法进行腐蚀测试,任何Atlas SF、BCX或CCX系列腐蚀试验箱都能满足这种要求。也作为一项Atlas提供的商业实验室测试服务。

阻燃性测试

- Atlas HMV水平燃烧阻燃性试验箱符合FMVSS 302 –“内部材料的阻燃性——客车、多用途客车、卡车和公共汽车(Effective 9-1-72)的要求。该标准规定了机动车辆乘员舱中所用材料的阻燃性要求,以及基于FVMSS 302的其他标准。

大规模日光模拟系统

Atlas提供大型定制的全光谱日光模拟和日光热负载系统,可集成到步入式/驶入式环境试验仓和风洞等系统中。Atlas使用专有的建模软件,为耐候老化或日光热负载测试定制设计光照解决方案, 并按照客户要求安装和控制系统。

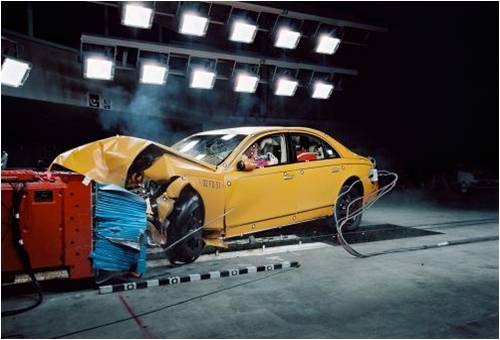

碰撞测试高速摄像照明系统

碰撞测试高速摄像照明系统

自1976年以来,Atlas定制系统中的汽车碰撞测试高速摄影照明系统的质量和性能得到了世界范围的公认。